When ordering branded workwear, you can usually choose whether to have your design screen printed or embroidered onto each garment.

Both methods have their advantages and disadvantages, so we’ve put together this handy guide to help you make the right choice.

Screen Printing

Screen printing on a T-shirt or other garment is done by squeezing inks through mesh screens directly on to the garment. It’s particularly good for bulk orders because the printers can use one mesh screen on multiple units.

Small text, large designs, and complex colour gradients also show up better on screen printed garments. Embroidery can only shrink so far before text becomes illegible, and it’s much more difficult to produce different colour gradients with embroidery threads. It will also be more expensive to produce a large design with embroidery due to the larger amount of work involved in producing it.

Screen printing is particularly well-suited to 100% cotton garments like T-shirts, or poly/cotton blends or other materials like those used in waterproof and hi-vis clothing. For customising T-shirts, screen printing is better than embroidery because it won’t cause the thinner material to pucker like embroidery does. Embroidery pokes holes into a garment, so it’s definitely not a good choice for waterproof clothing! Waterproof and hi-vis clothing also tend to be made of thicker and tougher materials than the fabric of an average t-shirt or polo shirt, so embroidering them is more difficult.

So, if you’re having T-shirts made for an event like a charity run or a promotional event, screen printing is probably the way to go.

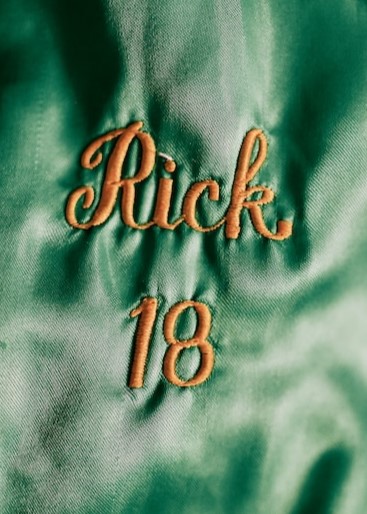

Embroidered workwear

Embroidery has one key advantage over screen printing: durability. Both methods should last a long time if cared for correctly, but embroidery generally lasts a lot longer than a print.

Typically, embroidery is used for small designs or logos, such as the Lacoste crocodile. It works very well with fleeces or polo shirts, which are often made of a durable fabric that can more easily withstand being embroidered. Because of this, a lot of businesses that have polo shirts as part of their uniforms tend to have them embroidered with the company logo.

So, if you’re having a workplace uniform created, you may want to go for embroidery. It can also work well on accessories like hi-vis hats.

Is screen printing cheaper than embroidery?

Neither option will always be cheaper than the other. The more cost-effective option will depend on various factors of the job itself, such as the size of the design, the garment quality and material, which company you order from, and the number of garments you need.

Commissioning a local designer or printer will save on shipping costs, for example, while a bulk order of office uniforms with embroidered logos might be cheaper than ones with printed logos due to the cost of inks. Embroidery services also tend to charge flat rates, regardless of colour complexity, but a screen printer may need to charge more for a particularly colourful design.

You’ll need to factor your budget into the decision-making process, but both methods can lead to great-looking garments.

Ultimately, it’s up to you to choose between embroidery and screen printing for your workwear. Here at My Printed Clothing, we make the customisation process as simple as possible. Just select a garment, upload your design, choose to have it printed or embroidered, and we’ll do the rest.

Buy Printed & Embroidered Clothing